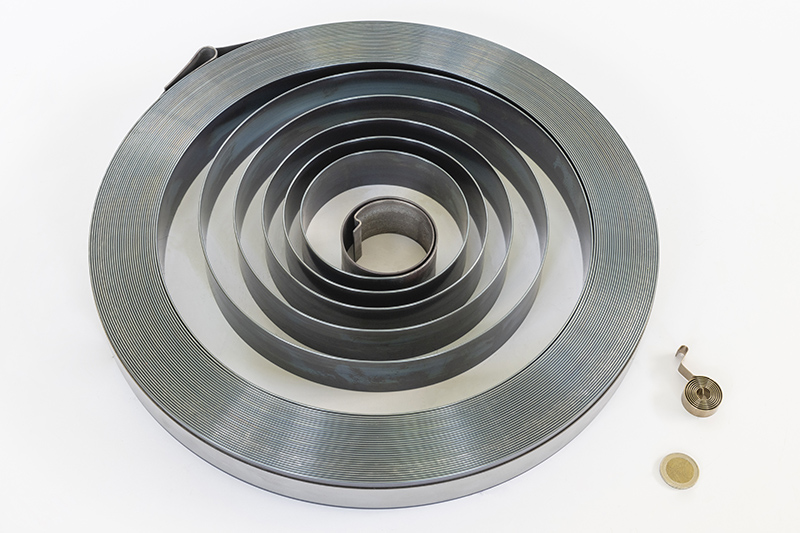

These springs are made by winding steel strip in retainer rings or iron bands, of the diameter required by the constumer case.

Some springs can be produced also from annealed steel strip and then hardened and tempered by specialized companies.

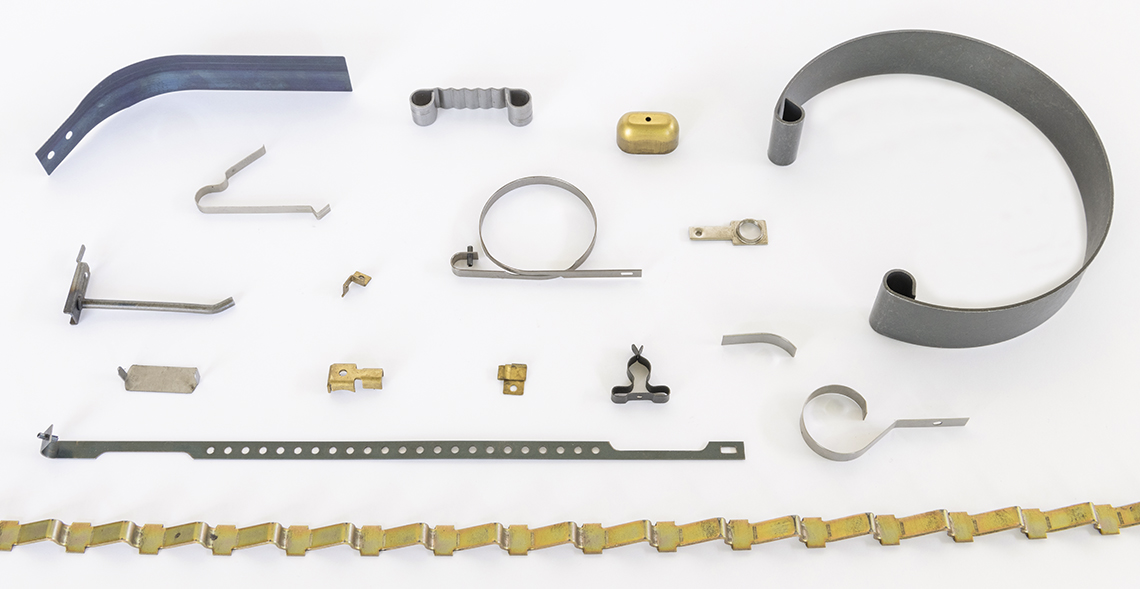

Inner and outer hooks (arbor and case ends) are produced according to the customer drawing and matching the features required, to improve the mounting process and the consequential winding and unwinding of the spring.

Depending on the different performance required (torque, number of turns, fatigue life), different working process are chosen to manufacture the springs: from simple winding of the steel strip (low performance) to the prestressing of the strip with heat treatment (maximum performance).

Common applications of power springs are shown in the following sample videos, and include the winding of small ropes, cables or strips in smaller products or all the applications in spring driven automatic reels for hose or electrical cables.